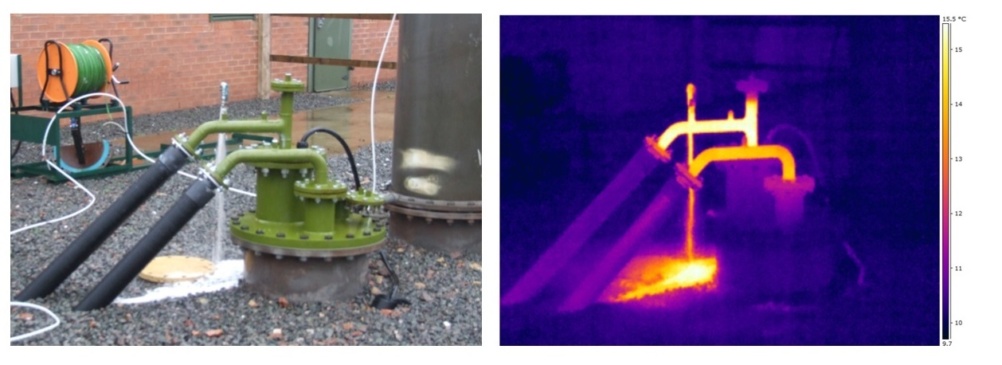

The above ground workings of the former Hebburn Colliery on Tyneseide, now home to a new geothermal energy district heating scheme. Image used by permission of the Coal Authority ©, 2020, All rights reserved

Earlier this summer, one of England’s last remaining coal mines – Durham’s Bradley site – brought the curtain down on more than 200 hundred years of production in the region.

And with only Derbyshire’s Hartington mine remaining, a sector that fuelled the industrial revolution and shaped the UK’s urban landscape is now one step away from becoming a footnote in our industrial history.

But whilst coal extraction is all but over, the mines themselves may still have a vital role to play in the UK’s energy mix as a host of green initiatives aimed at tapping into the vast labyrinth of tunnels, shafts and roadways beneath its towns and cities gather momentum.

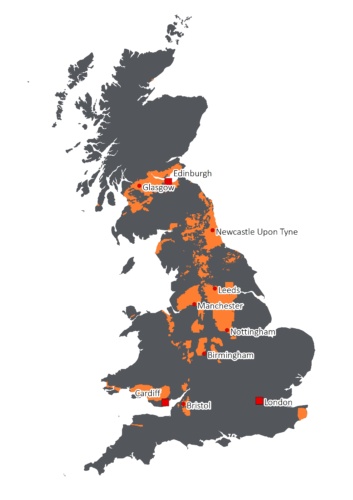

With many of the UK’s mines abandoned decades ago, and most signs of this historic activity lying deep underground, it’s easy to forget about the scale of the UK’s coal industry. But, astonishingly, as much as a quarter of the population of the UK (and around 14 per cent of its land area) sits above the coalfields. Indeed, it is thanks to the coal, and the industry it created, that these population centres exist at all.

For many years, this legacy of Britain’s industrial past has been viewed as a liability. Keeping it safe, managing its effects and dealing with the billions of litres of water that began to flow into the mines when the pumps were switched off is a twenty four-seven effort costing the tax-payer around £2.4 billion per year.

But in recent years, researchers, engineers and scientists have begun to ask whether this legacy of our polluting past, and in particular the huge volumes of mine water – heated by geological processes to temperatures as high as 40˚C – could actually help power the UK’s shift to a zero-carbon economy.

One particularly vocal evangelist for this green repurposing of the mines is Jeremy Crooks, head of innovation at the Coal Authority, the government agency responsible for looking after the mines.

“Mineshafts have always been a liability, but we look at them in a totally different way now,” Crooks told The Engineer. “When you look at the opportunities that sit around these mines this is no longer a liability: it’s an asset of strategic importance to the UK.”

Indeed, the Coal Authority now has around 30 different projects aimed at tapping into the estimated 2.2 million GWh of annually renewing zero carbon geothermal energy held within the mines.

When you look at the opportunities that sit around these mines this is no longer a liability: it’s an asset of strategic importance to the UK

Jeremy Crooks – Head of Innovation, The Coal Authority

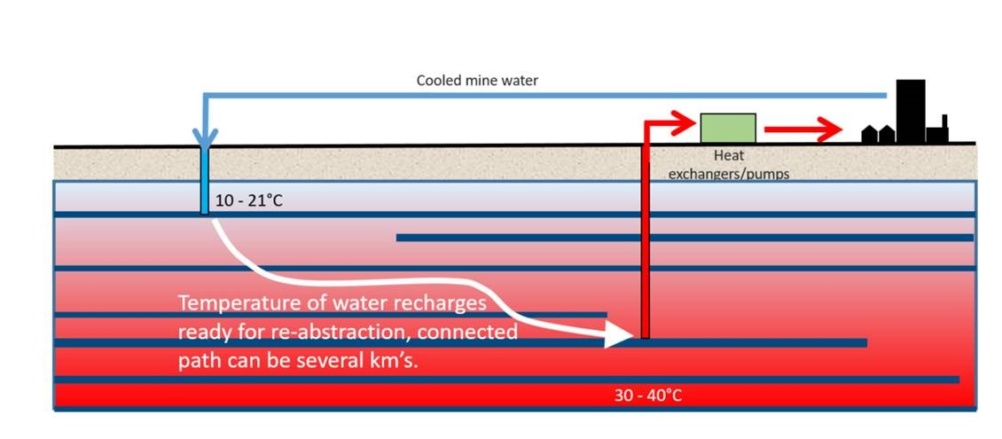

The core concept is simple: a borehole is sunk into the workings of the mine, water is pumped to the surface and fed into a heat pump or heat exchanger where it’s used to heat water that’s then circulated around a district heating system.

It is, he said, a massively efficient process. For mine water taken from close to the surface (typically 11 – 20˚C) heat pumps work at a coefficient of performance (COP) of 4 (i.e. for every 1kW of electricity you put in, you get 4kW equivalent back out in heat). And for higher temperature water taken from deeper mines, it becomes even more efficient. “If you go to warmer temperatures of 30˚C plus then you get a coefficient of performance of 10,” he added.

In the meantime, cooled mine water is reinjected back into the mine via a separate borehole so that it can be warmed all over again.

Positioning of these injection boreholes is key, as the aim is for reinjected water to travel the furthest possible distance within the mine, before it’s abstracted again.

Here the UK has a particularly useful tool at its disposal courtesy of so-called abandonment regulations – in place for more than 150 years – which placed a legal requirement on mine operators to file paperwork showing exactly where they mined.

Armed with this information – as well as historical data on mine temperatures – engineers are able to work with the complexity of the mine to identify the optimum locations for abstraction and reinjection points.

Crooks pointed to a scheme in Durham – where the boreholes are just 20m apart but the connected distance beneath the surface is 6.5km – as an example of the way in which this data is being used.

Whilst it’s clearly a precise art, it’s also one which is well understood, he added. “There’s nothing here that’s rocket science. The Coal Authority’s sunk 200 boreholes into mine workings, so we know how to do that; we treat 120 million cubic metres of mine water a year so that’s understood. Heat pumps and district heating are well understood. So we’re just pulling all of those together.”

The trickiest challenge, he suggested, is making district heating viable for retrofit to the UK’s stock of leaky old Victorian housing, which is why many of the current projects are focused on new build schemes.

One such initiative is a large 6MW scheme currently underway at the Seaham Garden Village development in county Durham. This will use low temperature water from the former Dawdon mine of around 18 to 20˚C to provide heating to around 1500 new houses and a number of community buildings. When up and running the scheme is expected to have around a tenth of the footprint of gas heating.

This scheme hits a particular sweet spot for district heating schemes because of the relatively low temperatures involved, said Crooks. The system heats the water to around 60˚C meaning that the thermal losses are lower than they would be with higher temperature water and there is no requirement for steel pipes, meaning a plastic distribution system can be used. “That’s significantly cheaper to put into the ground and there’s an established supply chain out there in the water industry,” said Crooks.

The coalfield communities were disadvantaged by the closure of the mines…there’s potential here that the mines as a low carbon, low cost source of energy could turn that all about face

Jeremy Crooks

Other geothermal projects currently underway include a 6MW installation in Gateshead (which will use geothermal energy from an operational mine water treatment scheme to deliver heat to homes and buildings) and a further £7 million scheme, which will use energy drawn from the flooded Hebburn Colliery, also in Tyneside, to heat a number of council buildings and homes in the town.

Alongside geothermal, Crooks’ group is also looking at the potential of using the mines as so-called “thermal flasks” which could store waste heat or heat from other sources such as solar power installations, that could then be fed back into heating networks at times of high demand. Above ground thermal stores are already widely used in Scandinavian countries for district heating schemes, but he said that the long narrow profile of mineshafts makes them particularly well suited to this application.

He revealed that the Coal Authority is now considering a potential development in Shawfair – a new town to be built largely on the site of the former Monktonhall colliery in Midlothian, Scotland – which, if it goes ahead, would represent the world’s first use of an abandoned mineshaft as a thermal flask.

Beyond individual energy schemes though, Crooks spies an even bigger opportunity, and believes that mines could be used as giant interseasonal energy stores where heat from a variety of sources – including waste plants, wind turbines, solar thermal panels and even sewage – could be used to elevate the temperature of the existing geothermal resource. Such an approach, could he said potentially elevate the water temperature to such a degree that there would actually be no requirement to put it through a heat pump or heat exchanger when you pull it back out again. “This has never been done at a large scale anywhere in the world so it could be an opportunity for the UK to really lead the world,” he said.

The possibilities are, he said, almost limitless. “What you’ve got is an enormous container below ground and all of these things you can do with it because it’s filled with water and water as a preferential transmitter of heat opens up all of these opportunities.”

If all the plans currently in the pipeline were to come to fruition it could be huge for the UK, said Crooks – creating new jobs, new SMEs and exportable expertise. Indeed according to the Institute for Public Policy Research (IPPR) investment in heat networks could create 81,000 jobs and generate as much as £22 billion in private investment into the UK economy.

As well as this, repurposing the mines could also have a profound impact on the communities that were left behind as the country turned away from coal.

“The coalfield communities were disadvantaged by the closure of the mines,” said Crooks. “They have a shorter lifespan, a health gap, and fewer employment opportunities. There’s potential here that the mines as a low carbon, low cost source of energy could turn that all about face. The coalfields could all of a sudden become the point where it’s the commercial place to be and to invest in going forwards. We shouldn’t lose sight of the fact that we’ve got this fantastic labyrinth of workings under the ground that was created by miners working in really difficult conditions. Every tonne of coal they abstracted – they wouldn’t have known it at the time – but they were creating an asset for the future of the UK and there’s something really poetic about that.”

Deep Drop

Edinburgh firm Gravitricity hopes to use its weight-based system to turn abandoned mines into giant underground energy stores.

Another technology developer eyeing up the untapped potential of the UK’s abandoned coal mines is Edinburgh startup Gravitricity, which has developed an elegantly simple gravity-based energy storage concept based on the use of large weights.

The system works by using electric winches to raise weights through vertical shafts when there is excess power on the grid. At times of demand, the controlled release of these weights is used to drive motors and generate power.

The firm’s lead engineer Miles Franklin said that the system marries the longevity of a mechanical engineering solution to the fast response time of newer energy storage technologies like lithium ion batteries and is perfect for meeting some of the energy storage challenges created by the rapidly changing profile of both generation and demand in the UK.

“We’re trying to do something that takes some of benefits of newer batteries like lithium ion which has been put on the grid in fairly large numbers as well as pumped hydro which is still 98 per cent of world’s grid-connected energy storage,” he said. “Pumped hydro is fantastic because it lasts a very long time. Lithium ion is good because it responds really fast and it’s easy to install, but its Achilles heel is if you cycle it more it won’t last very long. Our sweet spot is a long life – the maintenance requirements are well understood so we can achieve design life of decades – but with the fast response which will allow it to play a role in the kind of frequency balancing service that lithium ion is being used in.”

According to Gravitricity project development manager Chris Yendell, the potential for the technology is huge.

Research carried out for the company by KPMG identified 60,000 vertical shafts of 200m or greater in Germany alone. Indeed, many of these shafts as deep as 1000m. Meanwhile, following discussions with the Coal Authority, the team believes that in the UK there are at least 100 potentially viable deep vertical mineshafts. “Based on that you could look at a future portfolio in the UK of 2.4GWh of capacity, based on a 10MW peak system with a capacity of 24MWh” said Yendell.

For the moment though the company is concentrating on the development of its first physical system, an above ground, 250kW device that will be installed in the Port of Leith later this year.

This initial demonstrator will consist of a 16m high lattice tower containing two winches and two 25 tonne weights suspended from steel cables. During operation these weights will drop through 7m at 0.6m/s, generating 250kw of output.

Supported by a £640k Innovate UK grant, a sum matched by private money raised through two crowd funding exercises, this small scale demonstrator will, said Franklin, provide an incredibly useful snapshot of the technology’s capabilities and help advance the team’s understanding of some of the problems that would exist in full scale deployments. These include challenges around developing guidance systems for the weight, and how to deal with an emergency stop in the event of power loss from the grid. The demonstrator will help also help the team explore the use of multiple-weights – configured to operate in sequence – to increase the energy stored in a single shaft.

The team is hopeful that a larger scale underground system could follow, perhaps within the next two to three years, and Yendell confirmed that he has already identified five promising sites: two in the UK, and one each in Finland, Poland and the Czech Republic,

But taking the technology below ground will be far from straightforward said Franklin: “That brings in a whole new set of technical challenges: multiple winches, multiple motors per winch, deeper shafts with longer cables – so there are a lot of very interesting new control problems that need to be explored and solved.”

One of the key challenges will be around installation. The conditions within abandoned mines can vary dramatically and Franklin said that the team is doing a lot of work in both trying to understand what these variables are and how they could develop a modular system that enables it to be installed across all of those different environments with a minimum amount of fuss.

Although the technology is still at a relatively early stage, as with the geothermal applications discussed in this article many of the key components – such as the winches and cables – are already commercially available, and there’s no shortage of expertise in how to maintain and operate heavy engineering systems beneath the surface.

“Mine operators are very good at maintaining their systems so that they can run all of the time,” said Franklin. “They have lots of experience in planned maintenance and condition monitoring to ensure these things operate as much as possible, extending and understanding the life of cables, motors and brakes. None of it is extraordinarily complex, it just needs to be done right to ensure that the thing can keep going smoothly.”