Swedish energy company Vattenfall, mining company LKAB, and steel manufacturer SSAB in September started the world’s first pilot plant to produce “fossil-free” steel in Lulea, Sweden (Figure 1). As part of a joint initiative dubbed “HYBRIT,” the three companies plan to perform tests in several stages to explore the use of hydrogen produced via renewable and nuclear power as a replacement for coking coal in the direct reduction of iron (DRI) ore.

|

|

1. This September, HYBRIT, a joint initiative owned by Swedish energy company Vattenfall, mining company LKAB, and steel manufacturer SSAB, began test operations at a new pilot plant to produce “fossil-free” steel in Lulea, Sweden. Courtesy: HYBRIT |

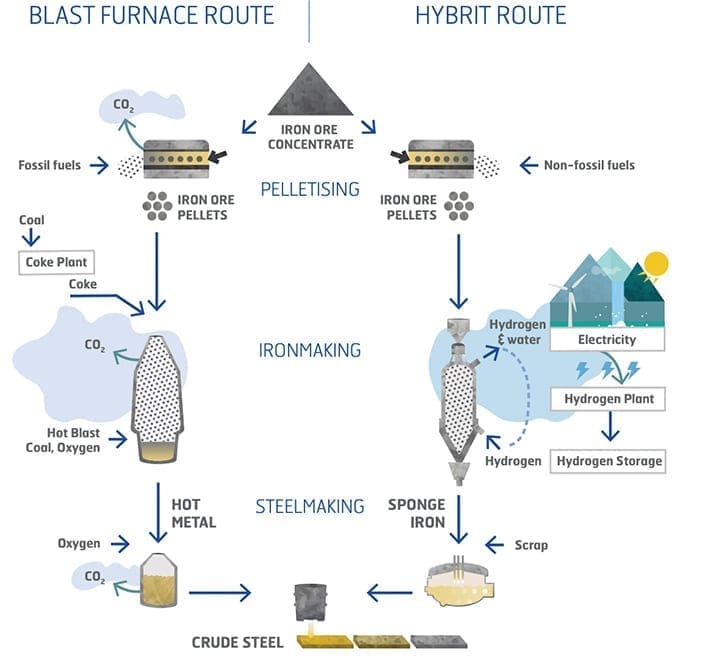

According to the companies, global steel demand is only slated to continue to rise as the world’s population grows and urbanization expands. However, it is already one of the largest carbon-emitting industries. As HYBRIT explains it, the ore-based steelmaking value chain starts at the iron ore mine, where the ore is processed in the form of pellets, or “fines.” At the steelmaking site, the iron ore is converted to metallic iron by reduction of the iron ore pellets with coke in a blast furnace. In the furnace, the iron oxide and carbon react to form carbon monoxide and carbon dioxide gases, as well as liquid metallic iron (which is further processed before being cast as semi-finished steel).

While this blast furnace approach route dominates most ironmaking, another approach used in parts of the world where natural gas is abundant is to use a so-called “direct reduction process,” where natural gas replaces coke as the main reductant, and the main product is solid “sponge” iron. However, in this process, the iron still needs to be melted using an electric arc furnace before steel is produced. HYBRIT’s process essentially emulates the direct reduction process, but it uses hydrogen gas as the main reductant instead of natural gas.

|

|

2. The HYBRIT system uses hydrogen—produced by electrolysis of water using fossil-free electricity— instead of coking coal, and releases water instead of carbon dioxide. Courtesy: HYBRIT |

HYBRIT said a pre-feasibility study for the concept completed in 2017 showed no major “unknown” technical obstacles, allowing construction for the unique test facility in Lulea to begin in summer 2018. At the pilot plant the three companies plan to carry out a series of tests between 2021 and 2024, first with natural gas, and eventually with hydrogen produced by electrolysis of water. The project will then move into a 10-year demonstration phase, and HYBRIT’s goal for now is to produce fossil-free steel by 2035.

If all goes well, the effort will yield a process that could be 20% to 30% cheaper than that for producing crude steel. That’s because “cost structures of fossil and fossil-free value chains are strongly dependent on the prices of coking coal, electricity and emission rights,” HYBRIT said. “An expected future shift in costs and market demands makes the fossil-free HYBRIT concept an attractive alternative.”However, the initiative also specifies a long list of potential challenges it must overcome, and among these are major technical hurdles. First, “the effect of carbon-free processing must be clarified,” it said. “Carbon is arguably the most important element in traditional iron- and steelmaking. Without carbon added in any substantial amount, there is a need to understand mechanisms and define process principles,” it explained.

HYBRIT also acknowledged that the process will rely on commercial hydrogen production technology that has “yet to be proven” on a large scale. “Controlling scale effects will thus be important for process functionality and economics,” it noted. Technology for large-scale hydrogen storage also still remains untested, and “fossil-free fuels and technologies” will be required to “replace existing fossil heat sources in the production system,” it said.

Finally, how the process will be integrated into the technical and economic value chain, and optimized at a system level, will also need to be established. It is clear, for example, that if renewable sources are used as a primary energy carrier, their consumption in Sweden alone could “increase in the order of 15 TWh, primarily to be used for hydrogen electrolysis and steel melting processes,” HYBRIT said.

HYBRIT plans to tackle some of these challenges itself. Plans call for experimental trials with “alternative fuels and a new heating technology” to take place in an experimental combustion furnace in Lulea, as well as at a pilot plant in Malmberget that will explore renewable biofuel heating. In parallel, HYBRIT is also planning a “new pilot project” in Lulea to support storage of hydrogen.

“Right now, we are investigating the possibility of building a temporary small pilot storage in connection to the old iron ore storage area at Svartöberget close to SSAB industrial area,” HYBRIT revealed. “When implemented in larger scale, this type of storage will secure ability of hydrogen to the industrial process during all hours of the day. It may also serve as grid balancing through load shifting. This will be an important component to support and stabilize the energy system in the future,” it said.