International Graphite has successfully commissioned its new graphite micronising plant in Collie, Western Australia.

The qualification-scale microniser will have a 200-tonne-per-annum (tpa) capacity, making it the largest qualification-scale microniser in Australia. The facility will also be the first to produce graphite products in Australia for customer acceptance testing.

The new plant is the predecessor to a 4000tpa commercial micronising facility the company expects to have operating at Collie within the next 18 months.

“We see breaking into the micronised graphite market as an important step in developing our Springdale–Collie mine-to-market strategy,” International Graphite managing director and chief executive officer Andrew Worland said.

“Demand for batteries will continue to grow. There are already more than 240 battery gigafactories operating worldwide, and up to 400 expected to open by 2030. All of them will need a secure source of graphite materials.

“Australian companies like us are in the box seat to deliver. We have the assets, the technical capability and Western Australia has an unparalleled reputation as a top resource supplier with outstanding ESG (environmental, social and governance) credentials.”

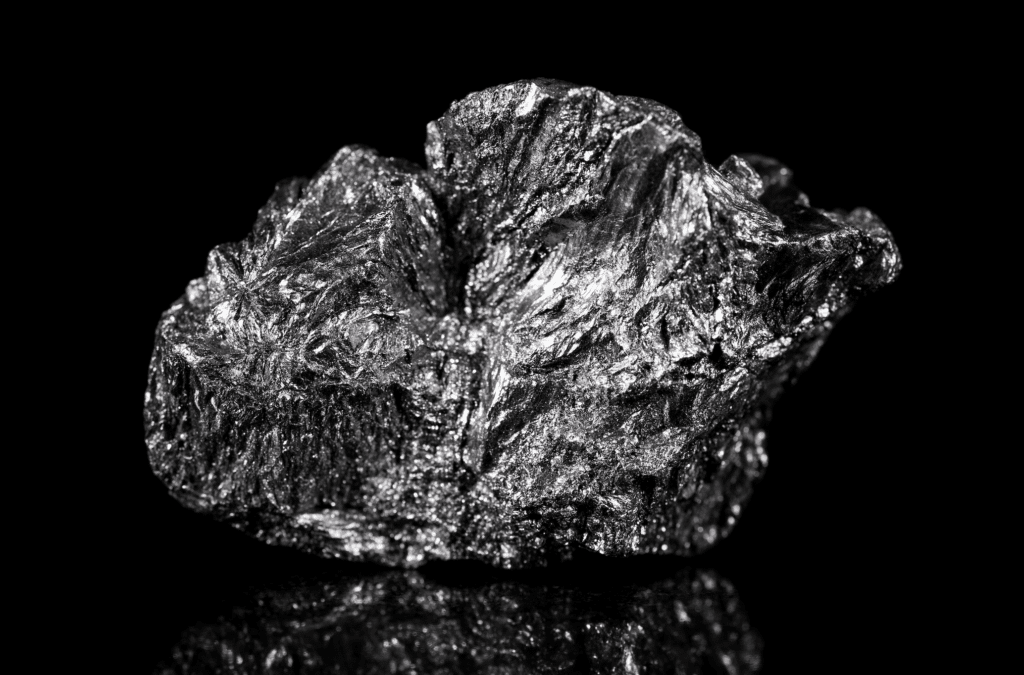

Along with other battery minerals such as lithium, cobalt and manganese, graphite is considered a critical mineral in Australia.

The Federal and WA Government have contributed $6.7 million in grant funding to International Graphite and more than 100 jobs are expected to be created at the Springdale project and the Collie downstream processing operation.

Micronised graphite is the first stage in producing battery anode material for battery-powered technologies used for electric vehicles and green energy storage.