Orica is set to expand its lead-free Non Primary Explosives Detonator NPED technology to manufacture the world’s first lead-free electronic blasting system range at its plant in Gyttorp, Sweden. This follows the successful introduction last year of the world’s first fully lead-free non-electric detonator range, Exel™ Neo, with early adopters reaping the benefits.

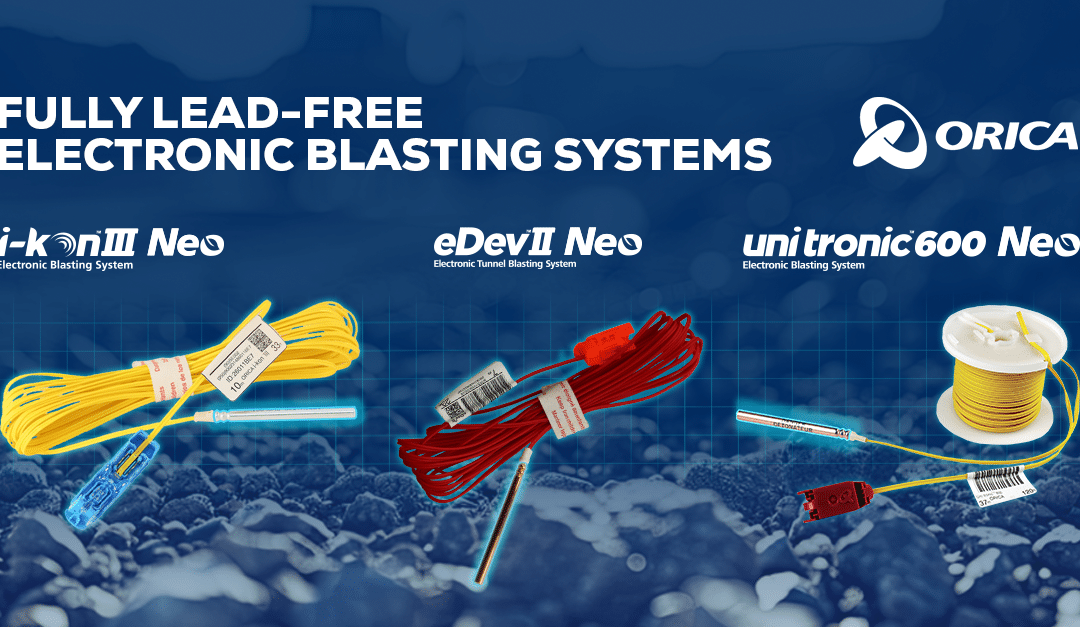

The lead-free alternative will be made available across the full range of electronic blasting systems, including the new eDev™ II Neo, uni tronic™ 600 Neo and i-kon™ III Neo, with the same proven performance and results as the current electronic blasting system range. The new fully lead-free variant will integrate Orica’s NPED technology, eliminating lead azide in the detonator. The product range will not contain any Substances of Very High Concern (SVHC) according to the European Union’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation[1].

Orica Chief Technology Officer Angus Melbourne said:

“With the expansion of our lead-free NPED technology to our market-leading electronic blasting systems range, Orica takes another step towards a more sustainable future for the industry. It’s a testament to Orica’s 150-year history of innovation and commitment to safer and more responsible solutions that deliver positive economic, social, and environmental outcomes. I would like to thank our teams around the world for their outstanding commitment to delivering innovative solutions to our customers and the industry.”

The development of the new technology has been underway for several years, with field trials and testing for compliance with the European Union’s (EU) mandatory conformity marking for goods sold within the European Economic Area (EEA), i.e., Conformité Européene, or CE testing to be conducted in the coming months. It is expected that the new lead-free electronic blasting systems range will be available for shipment in Europe by early 2025.

Among some of the key benefits, the new product range is manufactured close to our customer base in Europe and includes distinct safety and environmental benefits with all lead removed from the production process and from being released into the environment during the application. Orica is also investigating options for the reduction of plastics in the development of the new lead-free electronic blasting systems, further reducing its environmental footprint.

Orica’s Group Executive and EMEA President James Bonnor said:

“This is the first time Orica’s electronic blasting systems are being manufactured at our new state-of-the-art facility in Sweden, close to customers in Europe, ensuring supply security and optimisation. The facility will initially be used to assemble Orica’s standard EBS detonators before it will become the world’s first assembly line for the fully lead-free electronic blasting range based on NPED technology. Trials with our customers will get underway in July – August 2024 and we look forward to continuing to explore how Orica can use innovative technologies to assist our customers achieve their environmental, social and governance goals.”

Orica does not use lead or lead compounds in its manufacturing or production processes in Sweden and takes steps to seek assurances from its suppliers.