The Weir Group PLC (Weir), a global mining technology leader, has been awarded contracts

to supply its market-leading WARMAN® slurry pumps and CAVEX® hydrocyclones to Teck’s

Highland Valley Copper (HVC) Mine Life Extension (MLE) project in Canada.

Teck’s Highland Valley Copper Mine Life Extension Project aims to extend the mine’s operational life by

enhancing existing site infrastructure, addressing the growing demand for copper driven by the transition to

a low-carbon future. The project is expected to yield approximately 1.95 million tons of additional copper

over its lifespan.

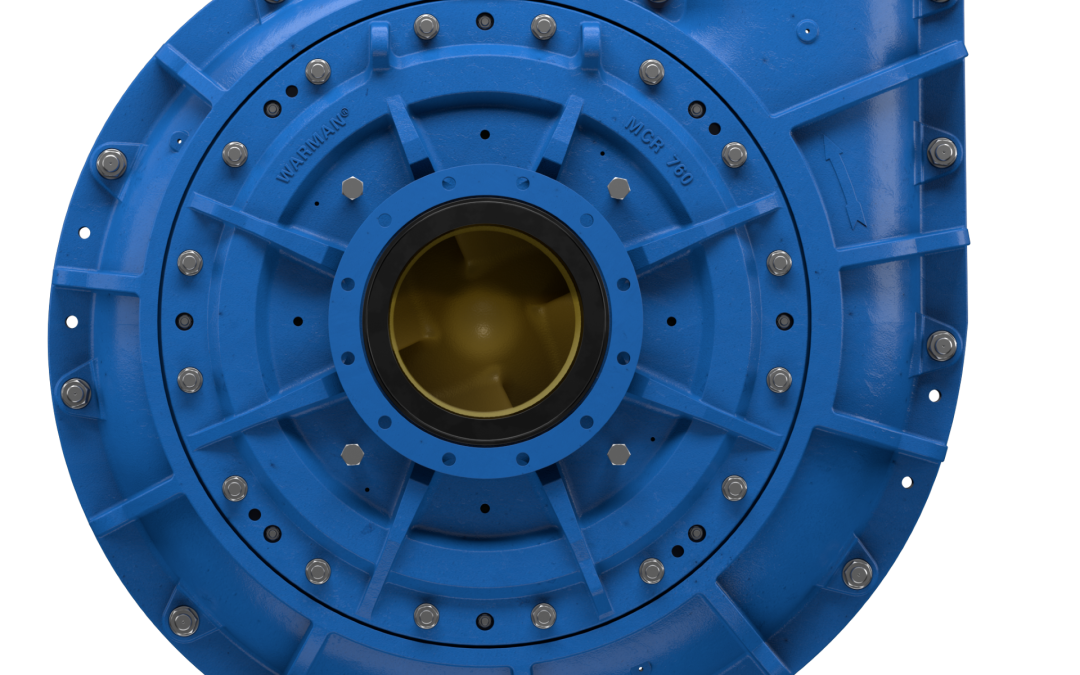

A cornerstone of this project is the WARMAN® MCR® 760 pump, which will be the largest mill circuit pump

in North America. This addition complements Weir’s existing and planned installations of equivalent-sized

pumps in South America and Australia. The WARMAN® MCR® 760 pump was developed to meet the

demand for mill circuit pumps that can handle unprecedentedly high flow rates, minimising the number of

operating lines in a plant, and addressing the global trend of declining ore grades that require increased

throughput for economical mineral recovery. The WARMAN® MCR® 760 pump is designed to maximise

wear life in arduous mill duties and facilitate easy and safe maintenance, regardless of an operator’s

maintenance schedule or approach.

In addition, Weir will supply CAVEX® 800CVX and 650CVX hydrocyclones for the MLE Project. HVC, with

their experience operating CAVEX® hydrocyclones, has chosen this trusted solution for its consistently high

classification efficiency, capacity and low maintenance requirements.

The MLE project will be fully supported by the local Weir service center in Kamloops, British Columbia,

ensuring that mission-critical equipment at the HVC mine operates efficiently. The proximity of this service

center means that any maintenance or support needs can be addressed promptly, minimising downtime

and helping the mine maintain its targets. This local presence is crucial for the mine’s operations, providing

reliable access to necessary parts and expert service.

Quinton Sutherland, Weir, Divisional Senior Product Manager, Pumps said:

‘Weir has a proven track record of supplying and supporting the largest, highest capacity mill pumps on the

market. Designing, manufacturing, and supporting pumps of this scale presents unique technical and

engineering challenges, which is why Weir’s team of experts, drawing on decades of experience supporting

customers across the globe, are the best choice when deciding who to trust with the most critical mill circuit

operations.

Issued by: The Weir Group PLC

1 West Regent Street, Glasgow, G2 1RW, Scotland 2

‘It’s an engineering and manufacturing feat that’s not easily replicable, which is why it’s important that we

can demonstrate to our customers that we’ve done this before, and they know that they can have absolute

confidence in us.

‘With declining ore grades and increased demand, miners are increasingly looking for solutions to increase

their throughput and our pumps play a pivotal role in ensuring they continue to meet their production

targets.

Phil Blondin, Weir, Director, Capital Sales North America said:

‘Weir prioritises being close to our customers wherever they are in the world. We have a service centre in

Kamloops – a close drive to HVC – and a local team that can provide service and maintenance support, as

well as an inventory program that encompasses the lifecycle of the products we supply.

‘This is the first mill pump this large in North America and, while Weir has manufactured and installed

pumps this size in other parts of the world, we recognise that having a service network to support

customers at every stage of the project is an essential part of what we’re offering.’