TotalEnergies’ innovative lubrication solutions are transforming mining operations with measurable environmental and performance benefits.

The Australian mining sector stands at a pivotal crossroads. While the local industry is still a global powerhouse, mounting pressures around sustainability and environmental impacts are bearing down.

Mining companies are responding to market demands for cleaner extraction methods through technological innovation and strategic partnerships. However, significant challenges persist, including volatile commodity prices, skills shortages and heightened community expectations around sustainability and transparency.

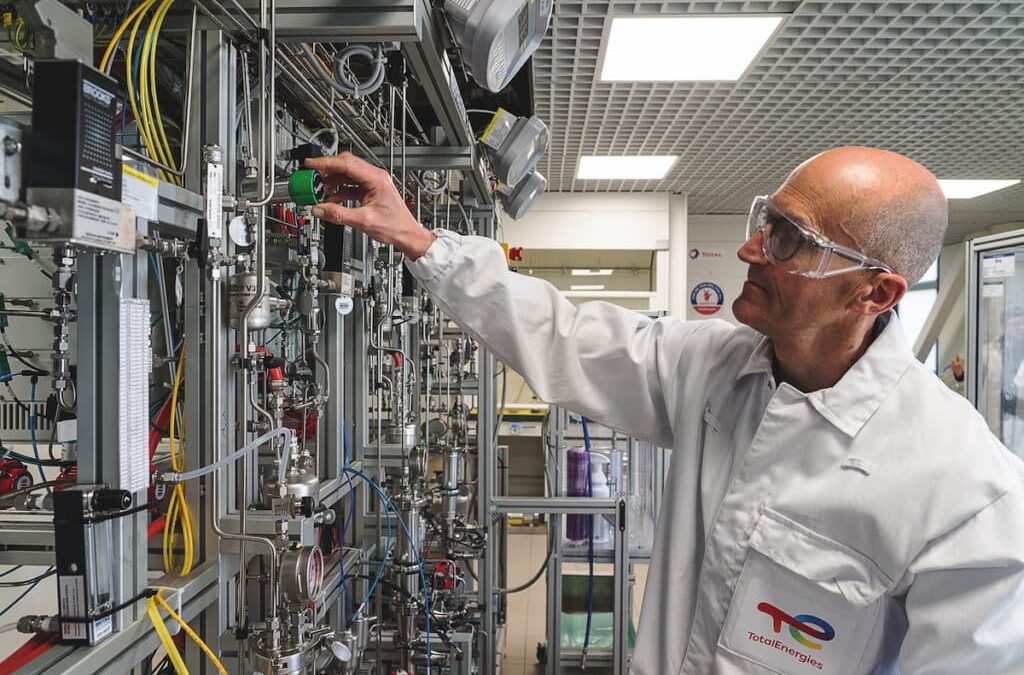

In this evolving landscape, integrated energy producer TotalEnergies has emerged as a willing innovation partner, investing heavily in research and development (R&D) to deliver solutions that address the complex pressures the mining industry is facing in Australia.

A holistic approach

TotalEnergies has carved out a distinct position in the Australian mining sector through its comprehensive, partnership-focused approach to lubrication solutions.

Rather than simply supplying standard products, the company leverages its global expertise and commitment to sustainability to deliver integrated services tailored to each mining project’s unique operational demands.

TotalEnergies national mining and industrial lubricants manager Andrew Druwitt said its methodology begins with detailed asset analysis.

“We identify every piece of equipment requiring lubrication across a mine site, and ensure optimal product selection aligned with OEM (original equipment manufacturer) specifications,” he told Australian Mining.

“This extends to understanding clients’ long-term fleet management strategies, helping reduce equipment wear and extend asset lifecycles.”

Setting TotalEnergies even further apart is its collaborative model between local Australian expertise and international innovation capabilities.

Information gathered from local mining operations is fed directly to global research teams, enabling development of lubricants specifically engineered for Australia’s extreme temperatures and diverse mineral extraction environments.

Druwitt said this approach positions TotalEnergies as a strategic partner rather than a traditional supplier, combining advanced lubricants with technical support to optimise equipment performance, reduce emissions, and lower the total cost of equipment ownership for mining clients.

Innovation in lubrication

TotalEnergies has introduced several innovations that directly address the Australian mining sector’s most pressing operational challenges.

The company’s next-generation lubricants are specifically engineered to withstand harsh mining environments, delivering remarkable performance improvements including up to a 30 per cent reduction in engine oil usage and reduced requirements for engine services.

Digital monitoring solutions represent another key innovation, providing real-time platforms for tracking lubricant performance and machinery health. These systems use predictive analysis to help mining operations reduce costly downtime and prevent equipment failures.

Safety is another key area for TotalEnergies’ R&D focus. It has developed on-site supply solutions and risk mitigation measures, particularly around high-pressure injection risks.

Druwitt said the company had also developed a real-time dust monitoring and suppressant package that has achieved strong results.

“It contributed to a 30 per cent reduction in water usage and reduced hazardous fine dust particles that add to respiratory health risks,” he said.

Lubricants are playing a larger-than-expected role in decarbonisation efforts across the mining industry. High-performance lubricants contribute directly to lower gas emissions by reducing friction, wear and overall energy consumption.

But, as Druwitt explained, TotalEnergies’ advanced lubricant technologies go even further.

“These lubricants work at the molecular level to truly optimise equipment performance,” he said.

“When friction is reduced within machinery components, less power is required for operation, resulting in decreased fuel consumption and emissions.”

The effect is multiplied in mining operations, where equipment operates continuously, often under extreme conditions. Even small gains in performance become game-changing when the machine is scheduled to run for 8000 hours or more in a year.

There are also lifecycle benefits on offer. By extending machinery lifespan through protection against wear and corrosion, advanced lubricants further reduce the operation’s broader carbon footprint. Replacement equipment, and the associated transportation logistics and disposal of the original item, are all required on a much longer timeframe.

Druwitt said TotalEnergies’ R&D investments focus specifically on understanding Australian mining applications, leading to product formulations that maximise performance and environmental benefits.

“Our commitment to continuous innovation ensures that lubricant technology keeps pace with evolving equipment designs, and increasingly stringent environmental requirements,” he said.

“That positions advanced lubricants as essential tools in the mining industry’s decarbonisation journey.”

Advancing with bio-lubricants

The innovation doesn’t stop there, and Druwitt believes bio-lubricants, derived from purely renewable resources, represent the next frontier in sustainable mining operations.

“We’re expecting significant growth across the Australian mining sector for these products,” he said. “They offer compelling performance characteristics, while also addressing key environmental concerns.”

The environmental advantages of bio-lubricants are substantial. With renewable inputs, they are naturally biodegradable and have lower-to-zero levels of toxicity. Leaks and spills thereby have no long-term impact on the environment. Still, there are some hurdles that have so far prevented widespread adoption of bio-lubricants.

Druwitt said fully-renewable products are not yet cost-competitive against traditional products, which has meant they are not yet compatible with a complete range of heavy-duty mining equipment.

But the industry direction is clear, and TotalEnergies is making significant investments to overcome these barriers.

“In the coming years, we are expecting bio-lubricants to transition from exceptions to standard practice,” Druwitt said.

The Australian mining industry faces an unprecedented transformation challenge, requiring a careful balance between economic imperatives and environmental responsibilities.

TotalEnergies, through innovative lubrication technologies and an unwavering commitment to decarbonisation, provides strategic partnership capabilities essential for navigating this transition successfully.

The integration of advanced lubricants and emerging bio-lubricant technologies offers mining companies practical pathways to enhanced operational efficiency.

As regulatory frameworks evolve and community expectations intensify, these innovations will prove increasingly vital for maintaining the Australian mining sector competitiveness on the global stage.