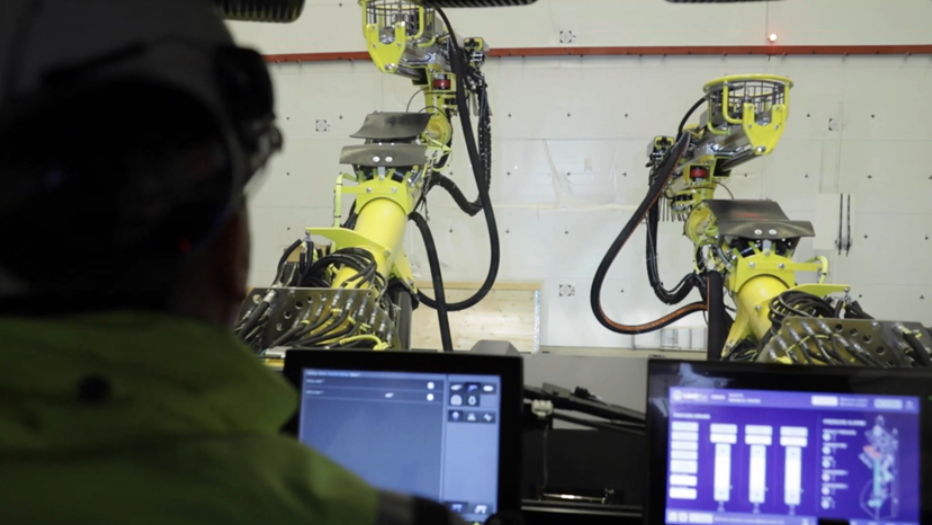

Orica and Epiroc’s advanced technologies integrated into the Avatel™ system

The world’s first mechanised development charging system, Avatel™ has been recognised for its engineering marvel in offering underground mining operators a significantly safer and productive solution to explosives delivery and blasting operations.

Avatel™, a customer needs driven solution that semi-automates explosives charging, has been awarded a 2021 POPULAR SCIENCE Best of What’s New Award in the Engineering category. The Best of What’s New is a definitive list of the 100 most incredible and innovative technologies and products from the past year across ten categories.

When commercially ready towards the end of 2022, Avatel™ will offer mine operators an effective solution to keep personnel out of harm’s way, by moving from traditional to mechanised development charging. Traditional development charging practices expose personnel to severe geotechnical hazards at the active face. Managing this exposure has forced Mine Operators to implement risk controls that slow the mining cycle, increase unit cost, and ultimately delay access to new production fronts.

Front impression of a commercially ready Avatel™ unit in an underground mine

Developed in partnership with Epiroc, Avatel™ will provide a step-change in safe and productive development charging operations – allowing a single operator to prepare and wirelessly charge a face from within the safety of an enclosed cabin, while providing superior blast control with Orica’s flagship technologies.

Orica Chief Technology Officer Angus Melbourne said: “We are extremely proud of this recognition by Popular Science as a testament to the ingenuity of the Orica and Epiroc teams who have developed this first-of-its-kind technology to ensure safety for mining personnel and drive productivity for the industry.

“The convergence of our advanced technologies will redefine how we approach face operations and is a significant step in the journey toward eliminating risks to personnel while unlocking substantial value and opportunities for our customers.”

Popular Science Editor-in-Chief Corinne Iozzio said: “The Best of What’s New Awards celebrates the year’s greatest feats of human ingenuity – the steps towards safer, healthier, more-sustainable, and happier days ahead.

“Despite the supply chain challenges making headlines in 2021, breakthroughs across all our categories have helped us glimpse a future brimming with possibilities. This collection, which includes everything from an artificial intelligence mapping more-efficient airline routes to mountain-bike shocks that adjust themselves on the fly, is full of items we’re proud to dub the Best of What’s New.”

An operator simulating the charging cycle from the safety of an enclosed ROPS and FOPS certified cabin.

Orica’s Vice President of Blasting Technology Adam Mooney said: “As mines advance deeper and ore bodies become more complex, the need for safer, automated solutions that support a more efficient mining cycle becomes more apparent. Development charging is the final step in the underground development cycle yet to be mechanised or automated. It is really inspiring to think that exposure to hazards at the face for development blast crews will soon be a thing of the past.”

Historically, mechanisation and automation of the development charging process has been constrained by the manual connections required to initiate a blast. With the introduction of Orica’s second generation of through-the-earth, wireless in-hole initiating system, WebGen™ 200, innovation in development charging has taken a leap forward.

Mining operations that adopt the Avatel™ solution will experience significant efficiency gains by having the opportunity to eliminate redundant support systems which are otherwise required to protect workers at the face. Customers will also benefit from productivity gains with reduced downtime associated with excess steel in blasted muck entering materials handling systems and downstream processes. Accelerated access to future production sources will be a key benefit to mine operators as well, ensuring them continued revenue generation by maintaining safe access to continue the development cycle in seismic or otherwise challenging ground conditions.