Dry bulk ports and terminals are in a state of constant change. The materials they handle change and so, too, do the quantities. Operators are constantly having to adapt to new requirements. They want to automate their activities as much as possible while also remaining flexible. They need more space for future expansions, and they are constantly facing the challenge of adapting their facilities to the increasing throughput, while at the same time paying ever more attention to avoiding dust emissions and improving their CO2 footprint. In projects such as these, BEUMER Group works together closely with its customers to develop efficient and new solutions.

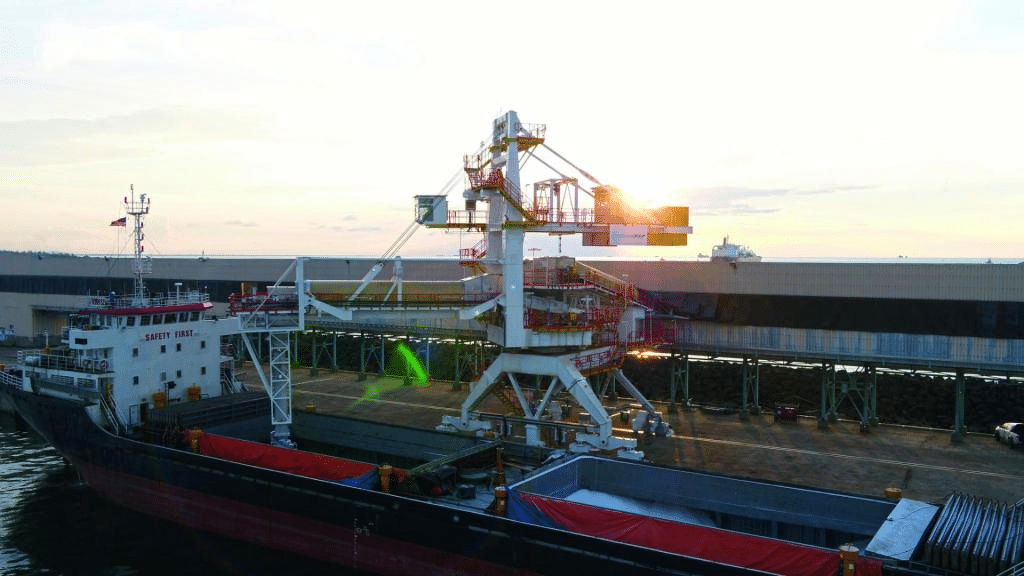

The ability to load ships quickly is a decisive productivity factor. It is important to adapt the technology implemented in ports to the local space constraints and the size of the vessels – as well as to take account of the characteristics of the transported material. “Ports are faced with the challenge of increasing their performance,” explains Lukas Paul, Head of Ports & Terminals at BEUMER Group. To remain competitive, operators must constantly expand their terminals. “That is just one of the challenges. It is necessary to ensure economically viable and environmentally responsible operation and, first and foremost, cost efficiency.” When it comes to dry bulk handling equipment, BEUMER Group is there to help. The system provider supports operators – starting with every aspect of conveyor technology and through to the loading of the ships.

“When customers come to us, we sit down with them and talk,” explains BEUMER expert Paul. “In most cases, they know their everyday workflows extremely well and are aware of where the weak points and bottlenecks are.” To ensure the efficient handling of dry bulk, they must constantly adapt or expand their terminals. However, the restricted space available in ports often presents a difficulty. This means that operators face the challenge of integrating new storage areas – and these are not always in the immediate vicinity of the port. To use these areas, environmentally friendly conveyor systems represent an alternative to trucks.

Belt conveyors as a cost-efficient alternative

Belt conveyors can be used to transport various bulk materials from and to the port. BEUMER Group supplies a variety of solutions depending on the intended use. Troughed belt conveyors, for example, permit high mass flows. They have an open design and are therefore suitable for coarse materials and very large volumes. Pipe conveyors, by contrast, have other specific advantages. The idlers shape the belt into a closed tube. This protects the transported material against external influences and also protects the environment against emissions such as dust or material loss. Panels with hexagonal cutouts and idler rollers in an offset arrangement keep the tube closed. Pipe conveyors are able to cope with tighter curves and larger angles of inclination than are possible with an open troughed belt conveyor. Their enclosed design also enables them to handle various bulk materials securely without any danger of cross-contamination. They also protect the health of the people who work at the facility or live nearby – for example, when bulk metal concentrates are being transported.

Lukas Paul remembers a project in Peru. To transport zinc, copper or lead concentrates mined by a number of different companies from the store to the terminal, the system provider installed a pipe conveyor measuring approximately 3,000 meters in length which transported more than 2,000 tonnes of this material per hour. However, there was a problem: The route passed through a military area with barracks for troops. The enclosed conveyor system reliably prevents the concentrates from coming into contact with the environment and conveys them to the ship’s holds without generating dust. The pipe conveyor is also equipped with filters, scrapers, a dust removal mechanism and a control system, making the need for any transfer points superfluous. “Our belt conveyor systems are an economical and environmentally friendly alternative to truck transport,” says Paul. “They allow operators to automate their processes and remove the burden of the manual work from their employees. This solution also reduces energy consumption.”

Adapting for improved performance